Bahan castingwangun produk kaya aMesin Jaw Crusher or Gyratory Crusher. Padha bantuan nggawe kabeh sakaBagian Cone Crusherkanggo aPalu Baja Mangan. Pilihan sing bener penting. Priksa tabel iki saka pengecoran Eropa paling dhuwur:

| Output wesi Cast taunan | 23.000 ton |

| Tingkat Cacat | 5–7% |

Ilmu material kalebu logam, keramik, polimer, lan komposit. Ngerti materi casting sing tepat mbantu para insinyur ngedongkrak kualitas lan ngilangi sampah.

Takeaways Key

- Milih bahan casting sing tepat, kayata wesi, baja,alumunium, utawa plastik, langsung mengaruhi kualitas produk, biaya, lan kinerja.

- Bahan ferrous ngemot wesi lan kuwat nanging bisa karat, dene bahan non-ferrous kayata aluminium lan tembaga tahan teyeng lan luwih entheng.

- Plastik lan keramik nawakake keuntungan unik kayata tahan karat lan toleransi panas, saengga cocog kanggo aplikasi khusus.

Jinis Utama Bahan Casting

Bahan Casting Ferrous: Besi lan Baja

Bahan casting ferrous kalebu wesi lan baja. Logam kasebut ngemot wesi minangka unsur utama. Dheweke main peran gedhe ing mesin abot lan konstruksi. Wesi lan baja nduweni sifat sing beda. Tabel ing ngisor iki nuduhake carane mbandhingake:

| Properti / Fitur | Cast Iron | Baja (kalebu baja ringan lan karbon) |

|---|---|---|

| Kandungan Karbon | 2–4,5% | 0,16–2,1% |

| Sifat Mekanik | kekuatan compressive dhuwur; rapuh | Ulur; kekuatan tensile beda-beda |

| Tahan karat | Luwih apik ing udara sing polusi | Corrodes luwih cepet |

| Kemampuan mesin | Gampang (wesi abu-abu); atos (wesi putih) | Apik, beda-beda miturut jinis |

| Aplikasi | Blok mesin, rotor rem | Gir, spring, bagean otomotif |

Bahan casting wesi bisa digunakake kanggo blok mesin lan omah pompa.Bahan pengecoran bajamathuk pindah, spring, lan akeh bagean mobil. Saben jinis ndadekke kekuatan dhewe kanggo meja.

Bahan Casting Non-Ferrous: Aluminium, Tembaga, Magnesium, Seng

Bahan casting non-ferrous ora duwe wesi minangka unsur utama. Aluminium, tembaga, magnesium, lan seng kalebu klompok iki. Logam iki luwih entheng tinimbang wesi lan baja. Bahan casting aluminium populer kanggo bagean mobil lan pigura pesawat. Bahan casting tembaga bisa digunakake ing bagean listrik amarga bisa nindakake listrik kanthi apik. Bahan casting magnesium lan seng mbantu nggawe bagean entheng kanggo elektronik lan alat. Logam non-ferrous tahan teyeng lan menehi kekuatan apik kanggo bobote.

Bahan Casting Liyane: Plastik lan Keramik

Sawetara bahan casting dudu logam. Plastik lan keramik menehi keuntungan unik. Plastik bisa mbentuk wangun rumit lan tahan korosi. Keramik tahan panas dhuwur. Wong kuna nggunakake bahan casting keramik kanggo leleh tembaga. Keramik modern, kayata nano-zirconia, nuduhake kinerja sing luwih apik. Padha duwe kekuatan mlengkung dhuwur, kateguhan, lan resistance goresan. Keramik iki mbantu nggawe bagean tipis lan kuwat kanggo telpon lan jam tangan.

Plastik lan keramik mbukak lawang anyar kanggo bahan casting, utamane ing ngendi tahan panas utawa wujud khusus.

Properties lan Panggunaan Jinis Material Casting

Bahan Casting Besi

Material casting wesi stands metu kanggo kekuatan ing komprèsi. Wong asring digunakake kanggo kolom, blok mesin, lan mesin abot. Wesi wesi abu-abu ngemot serpihan karbon, sing nggawe mesin gampang nanging uga rapuh. Wesi tuang putih, kanthi karbon minangka karbida wesi, menehi kekuatan tarik lan kelenturan sing luwih apik.

- Kakuwatan:

- Nangani beban abot kanthi apik.

- Apik kanggo bagean sing ora mlengkung.

- Kekirangan:

- Brittle lan bisa break ing tension.

- Rawan teyeng, utamane ing papan sing lembab.

Nambahake unsur kaya silikon, nikel, utawa kromium bisa ningkatake ketahanan lan daya tahan karat. Pengecatan lan inspeksi reguler mbantu nyegah karat lan njaga casting wesi kanthi apik.

Tes nuduhake yen wedhi digunakake ing casting wesi bisa nangani panas dhuwur, nanging Rampung lumahing gumantung ing ukuran gandum wedhi lan wangun. Iki mengaruhi carane Gamelan utawa atos prodhuk final ngrasa.

Bahan Baja Casting

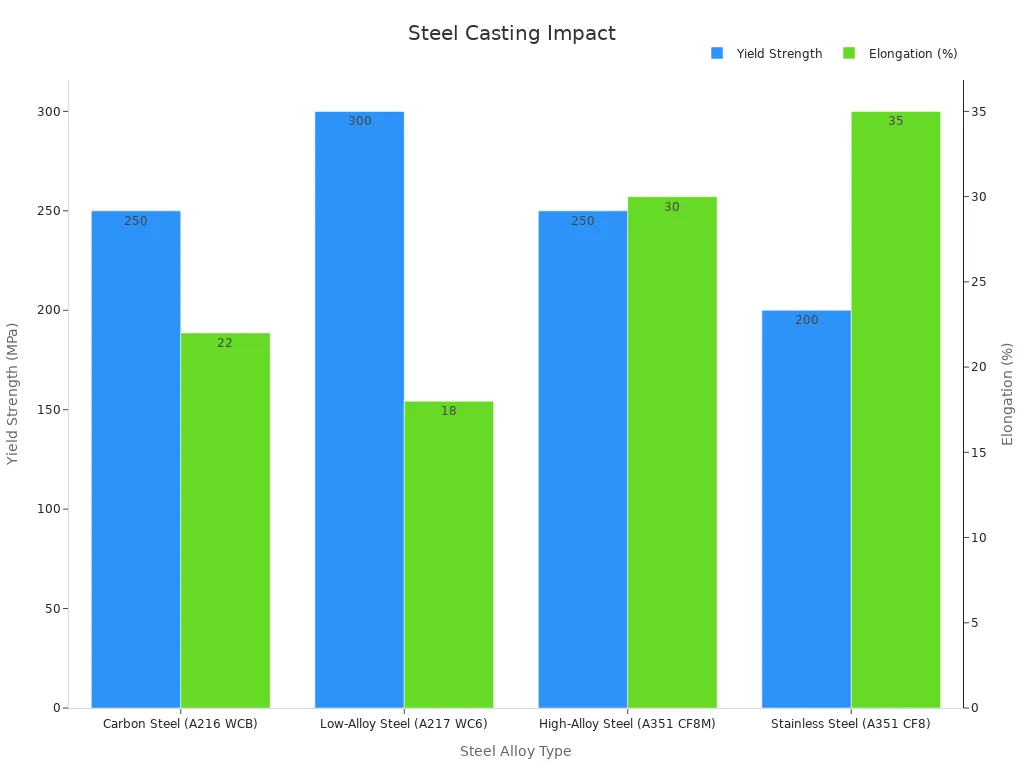

Bahan casting baja nggawa campuran kekuatan, daktilitas, lan kateguhan. Wong milih baja kanggo gear, spring, lan bagean otomotif amarga bisa nangani ketegangan lan kompresi. Sifat-sifat baja diganti kanthi paduan lan perawatan sing beda.

| Tipe Paduan Baja | Kekuwatan Hasil (MPa) | Kekuwatan Tarik (MPa) | Elongation (%) | Tahan karat |

|---|---|---|---|---|

| Baja Karbon (A216 WCB) | 250 | 450-650 | 22 | mlarat |

| Baja Paduan Rendah (A217 WC6) | 300 | 550-750 | 18 | Adil |

| Baja Paduan Tinggi (A351 CF8M) | 250 | 500-700 | 30 | Banget |

| Baja tahan karat (A351 CF8) | 200 | 450-650 | 35 | Banget |

Kinerja baja gumantung carane digawe. Pendinginan sing luwih cepet nggawe biji sing luwih cilik, sing nggawe baja luwih kuwat. Pangobatan panas lan cara casting sing ati-ati uga bisa nambah kateguhan lan nyuda cacat kaya pori-pori.

Bahan Aluminium Casting

Bahan casting aluminium misuwur amarga bobote entheng lan keluwesan. Iku umum ing bagean mobil, pigura pesawat, lan elektronik. Aluminium stands metu kanggo rasio kekuatan-kanggo-bobot apik lan resistance banget kanggo teyeng.

| Properti / Aspek | Cast Aluminium | Cast Steel | Wesi Grey |

|---|---|---|---|

| Kapadhetan | 2,7 g/cm³ | 7,7–7,85 g/cm³ | 7,1–7,3 g/cm³ |

| Kekuwatan Tensile | 100–400 MPa (nganti 710 MPa kanggo sawetara paduan) | 340–1800 MPa | 150–400 MPa |

| Titik Lebur | 570–655°C | 1450–1520°C | 1150–1250°C |

| Konduktivitas termal | 120–180 W/m·K | Moderate | ~46 W/m·K |

| Konduktivitas Listrik | apik | mlarat | mlarat |

| Kemampuan mesin | Gampang | Moderate | Apik nanging rapuh |

| Tahan karat | Banget | Moderate | mlarat |

| Getaran Damping | Moderate | apik | Banget |

| biaya | Kurang kanggo produksi massal | dhuwur | Moderate |

- keuntungan:

- Ndadekake wangun rumit kanthi akurasi dhuwur.

- Ngirit energi amarga titik leleh sing luwih murah.

- Tahan korosi, saengga luwih tahan ing njaba ruangan.

- Apik kanggo produksi volume dhuwur.

- Watesan:

- Ora kuwat kaya baja.

- Bisa brittle ing sawetara wesi.

- Perlu kontrol sing ati-ati supaya ora ana cacat kaya porositas.

Analisis statistik nuduhake yen kualitas aluminium nyawiji lan anané cacat duwe pengaruh gedhe ing kekuatan lan kateguhan. Insinyur nggunakake tes lan piranti lunak khusus kanggo mriksa lan nambah kualitas casting.

Bahan Tembaga Casting

Bahan casting tembaga kondhang amarga konduktivitas listrik lan termal. Wong nggunakake coran tembaga ing bagean listrik, pipa, lan barang-barang hiasan. Wesi tembaga, kayata tembaga lan kuningan, menehi kekuatan ekstra lan tahan korosi sing luwih apik.

| Sampel Paduan | Konduktivitas Listrik (% IACS) | Microhardness (Vickers) | Kekuwatan Hasil (MPa) |

|---|---|---|---|

| EML-200 | 80% | Dibandhingake karo EMI-10 | 614 ± 35 |

| EMI-10 | 60% | Dibandhingake karo EML-200 | 625 ± 17 |

Pangobatan kaya undercooling jero bisa ningkatake konduktivitas tanpa kelangan kekuatan. Nambah unsur kayata seng utawa timah uga bisa nambah resistance nyandhang lan daya tahan. Casting tembaga bisa digunakake kanthi apik ing lingkungan sing atos amarga tahan korosi, utamane nalika dicampur karo logam liyane.

Bahan Casting Magnesium

Bahan casting Magnesium minangka sing paling entheng saka kabeh logam struktural. Iku sampurna kanggo bagean sing kudu kuwat nanging ora abot, kaya ing mobil, pesawat, lan elektronik. Wesi Magnesium nduweni rasio kekuatan-kanggo-bobot sing dhuwur lan gampang kanggo mesin.

- Fitur utama:

- Banget entheng, sing mbantu ngirit bahan bakar ing kendaraan.

- Kaku lan castability apik.

- Kekuwatan spesifik sing dhuwur, utamane ing wesi cast.

Tes eksperimen nuduhake yen nambahake bolongan utawa wangun khusus bisa nggawe magnesium luwih entheng tanpa kelangan kekuwatan. Nanging, magnesium bisa gampang korosi, mula lapisan utawa unsur paduan asring digunakake kanggo nglindhungi.

Bahan Seng Casting

Bahan casting seng asring digunakake kanggo bagean cilik lan rinci. Gampang kanggo nyithak lan ngisi cetakan kanthi apik, dadi apik kanggo peralatan, dolanan, lan piranti keras. Wesi seng menehi kekuatan lan kateguhan sing apik kanggo bobote.

- Kaluwihan:

- Banget kanggo nggawe wangun Komplek.

- resistance karat apik.

- Titik leleh sing sithik ngirit energi sajrone casting.

- Tantangan:

- Ora kuwat kaya baja utawa aluminium.

- Bisa dadi brittle liwat wektu, utamané ing kahanan kadhemen.

Casting seng umum ing industri otomotif lan elektronik amarga nggabungake presisi kanthi efektifitas biaya.

Bahan Casting Plastik

Bahan casting plastik mbukak akeh pilihan desain. Iku entheng, tahan korosi, lan bisa njupuk meh kabeh wangun. Wong nggunakake casting plastik ing piranti medis, barang konsumen, lan bagean otomotif.

- Sifat Mekanik:

- Kekuwatan, kaku, lan kaku gumantung saka jinis plastik lan cara digawe.

- Nambahake serat kaya karbon utawa kaca bisa nggawe plastik luwih kuwat.

| Properti / Material | Woodcast® | Bahan Casting Sintetis | Plester Paris (PoP) |

|---|---|---|---|

| Kekuwatan Kompresi | dhuwur | Ngisor | rapuh |

| Kekuwatan Tensile | Ngisor | Luwih dhuwur | rapuh |

| Kekuatan lentur (MPa) | 14.24 | 12.93–18.96 | N/A |

| Tahan banyu | apik | beda-beda | mlarat |

Castings plastik bisa nangani banyu lan panas uga, gumantung ing materi. Sawetara ora beracun lan aman kanggo panggunaan medis. Liyane bisa ngemot bahan kimia sing kudu ditangani kanthi ati-ati.

Bahan Casting Keramik

materi casting Keramik stands metu kanggo kemampuan kanggo nangani suhu dhuwur. Keramik iku atos, awet, lan ora karat. Wong digunakake ing elektronik, aerospace, lan malah perhiasan.

- Sifat termal:

- Bisa tahan suhu nganti 1300 ° C.

- Banget kanggo insulasi lan tameng panas.

- Ketahanan:

- Serat keramik fleksibel bisa digunakake ing isolasi sing bisa digunakake maneh kanggo pesawat ruang angkasa.

- Keramik canggih nggabungake kekuatan dhuwur kanthi konduktivitas termal sing kurang.

Peneliti wis ngembangake bahan keramik anyar sing kuwat lan fleksibel, saengga cocog kanggo lingkungan sing ekstrem kaya angkasa utawa manufaktur berteknologi tinggi.

Bahan casting Keramik tetep wujud lan kekuatane sanajan ing panas banget, kang ndadekake wong terkenal kanggo akeh aplikasi modern.

Milih bahan casting sing tepat mbentuk kualitas produk, biaya, lan kinerja. Insinyur mbandhingake cara lan sifat casting nggunakake tabel lan studi kasus ing donya nyata kanggo cocog karo saben materi kanthi nggunakake sing paling apik. Ngerti rincian kasebut mbantu tim ngrancang bagean sing luwih apik, ngirit dhuwit, lan ngindhari kesalahan sing larang.

FAQ

Apa prabédan utama antarane bahan casting ferrous lan non-ferrous?

Bahan ferrous ngandhut wesi. Bahan non-ferrous ora. Jinis ferrous asring luwih bobot lan luwih cepet karat. Jinis non-ferrous tahan karat lan aran luwih entheng.

Apa engineers milih aluminium kanggo casting?

Aluminium bobote kurang saka baja. Iki tahan karat lan gampang dibentuk. Insinyur seneng karo komponen mobil, bingkai pesawat, lan elektronik.

Bisa plastik lan keramik nangani panas dhuwur?

Keramik nangani panas banget. Plastik biasane nyawiji ing suhu sing luwih murah. Insinyur milih keramik kanggo oven utawa mesin, dene plastik cocog karo proyek sing luwih adhem.

Wektu kirim: Jun-17-2025